Emerald is among the most precious gems, and it is much valued since centuries. Emerald belongs to the family of beryls, which also includes Aquamarine and Morganite. As a result of its popularity, many scientists have developed various synthesis processes to create synthetic emerald. Among those processes, hydrothermal dissolution is today the predominantly used technique.

Synthetic hydrothermal emerald is created in laboratory with the aim of reproducing natural emerald. Both materials share the same physicochemical, optical, and crystallographic properties.

One of the very few significant differences between them is that natural emerald comes from natural deposits, whereas synthetic emerald comes from a laboratory process and is created by humans.

History

The first hydrothermal synthesis tests were carried out in 1845 to produce quartz of microscopic dimensions. Then from the 1950’s, consequently to many improvements, humans will manage creating a greater diversity of crystals, of bigger and bigger dimensions, and better and better quality.

This technique is used to create synthetic quartz and emerald mainly, it however allows the creation of other synthetic (sapphire, ruby) or artificial (YAG) stones.

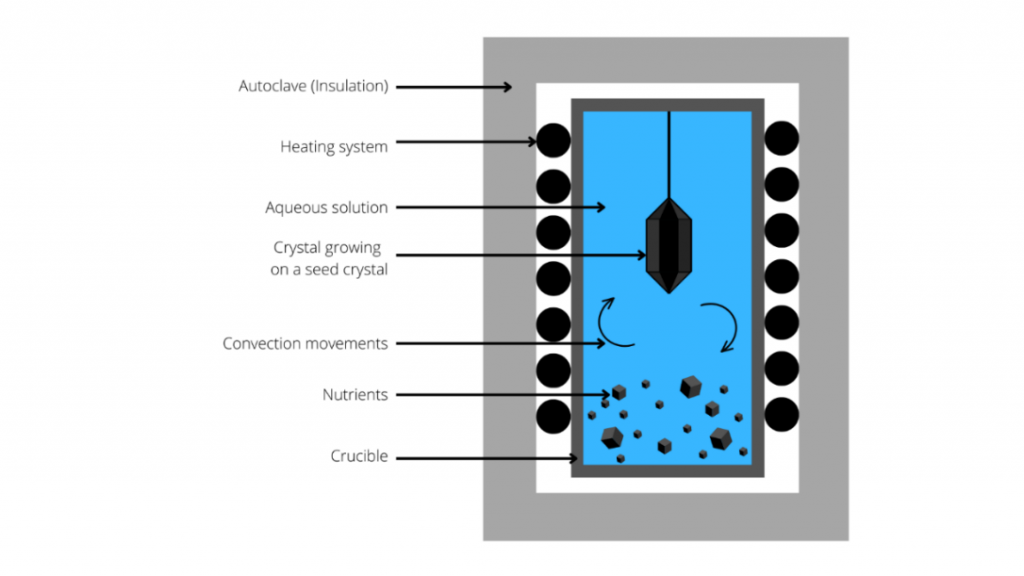

The aim of this synthesis process is to get as close as possible to the conditions that result in natural hydrothermal crystals to grow. In geology, this relates to the circulation of warm water containing dissolved minerals, which will settle by the effect of precipitation, under high temperature and pressure.

Process

Crystal growth is achieved in an autoclave (hermetical metal vessel), designed to withstand the high pressures it is put under. Temperature required is between 300 et 600°C and varies depending on the type of stone to synthetize.

The autoclave is filled up with water that dissolves the components of the crystal to be synthetized. Prior to this operation, a seed crystal is placed in the autoclave. Flow movements get components settling on the seeds and thus crystallizing the synthetic material.

Dying agents can be added to the solution (e.g., chromium, iron, cobalt, …). It is indeed necessary to add chromium to a synthetic beryl to produce hydrothermal synthetic emerald.

Once the rough material is crystallized, it is ready to be cut into stones. And this is how we can eventually propose hydrothermal synthetic emeralds, ready to be set on jewels.